CMMT™: Putting Affordable Mass on Target

As a company, Lockheed Martin has joined its customers on some amazing journeys, all of which started with an invitation to imagine what’s next. Imagine being the first to land a spaceship on a new world. Imagine hitting a bullet with another bullet in space, far from vulnerable citizens and settlements, to defeat a deadly threat. Imagine flying higher and faster than anyone else in history, or in aircraft invisible to radar, or in tactical fighters so revolutionary they require a new generational category just to contain them. In partnership with its customers, Lockheed Martin was the first to realize these visions, and others like them.

Today, everything is moving faster, and our customers have a critical capability gap to fill: a new breed of air vehicle that is highly adaptable and affordable—and can be produced and delivered as fast as it is expended.

That’s a pretty tall order, one requiring a transformation of the way the defense industry does business. And that’s a journey that’s well underway at Lockheed Martin.

Lockheed Martin has launched 1LMX, the largest internal program ever undertaken by the company, to re-engineer its internal processes. It is providing the automations and capabilities required to drive efficiency, increase velocity, and enhance our key captures and programs. It’s a complete overhaul of the powerful engine that drives our innovation and production at faster speeds, lower cost and greater agility.

And one of the early beneficiaries of 1LMX was a program called Rapid Dragon.

Demonstrating Rapid Dragon’s ability to put mass on target was a critical first link in the Affordable Mass chain, one that required best-in-industry agility and speed to achieve.

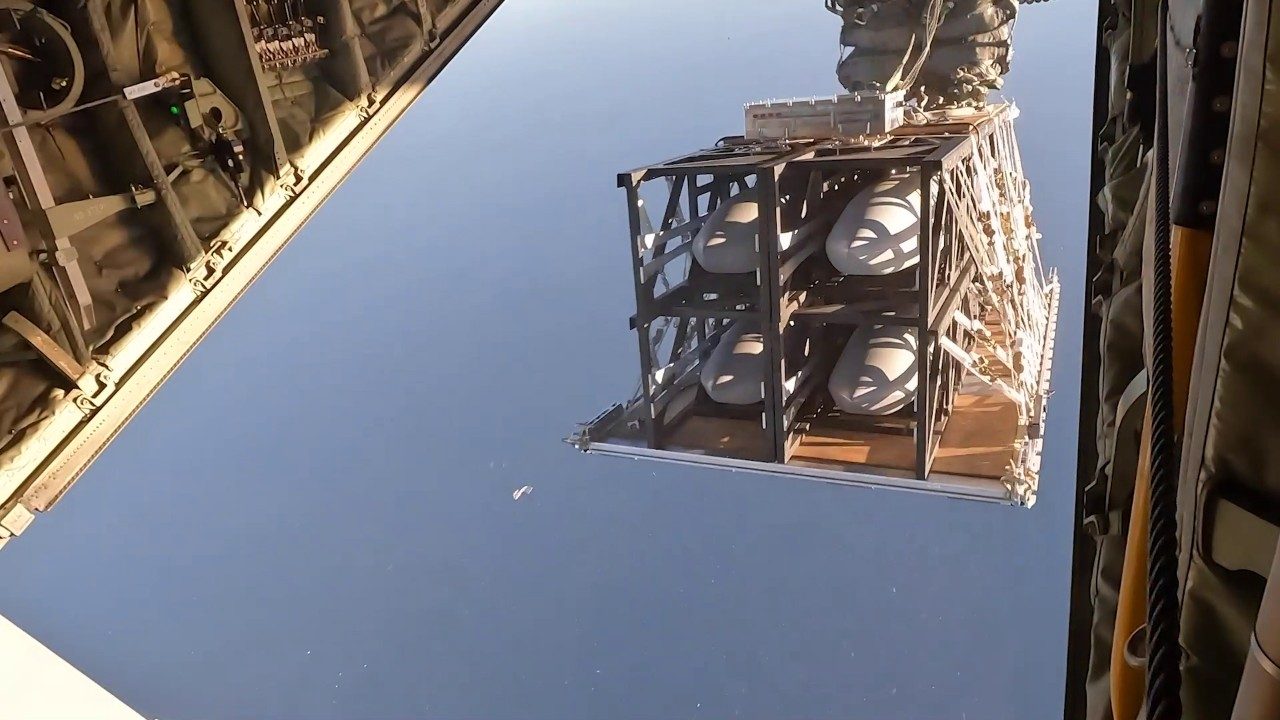

The Rapid Dragon journey began with a simple proposition: that the Air Force launch its affordable mass revolution by showing the viability of palletized deployment—and do it fast. In the ensuing months a plan came together, one using assets already in Air Force inventory. And everyone agreed the need for speed would go right on the tin.

With our Air Force partner, we kicked Rapid Dragon off in early 2021 with a blank sheet of paper. We participated in three customer exercises. We conducted our first flight. All in the first 10 months.

We followed that up with four live-fire strike missions from airlifters to demonstrate the feasibility of palletized deployment in a tactical environment—two at U.S. test ranges and two abroad. We also deployed additional effects and designed pallets that lower cost and weight.

This is how we are executing programs today: recognizing a capability gap, partnering with customers who share a vision and moving fast to fill it.

And our efforts have been recognized by industry peers. In 2023, the Air Force-Lockheed Martin Rapid Dragon team received an Aviation Week special Program Excellence award for developing a first-of-kind weapon system and executing with agility. What we did is so remarkable that the industry judges have only given this specific award four times in 20 years.

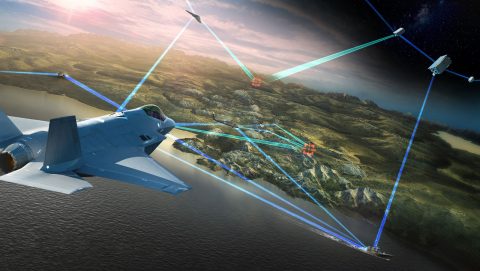

Lockheed Martin is flying a CMMT that deploys from airlifters to put affordable mass on target.

While preparing Rapid Dragon for fielding, we’ve been developing affordable mass weapons to support the Air Force mission—and a few others. The Common Multi-Mission Truck (CMMT, pronounced “comet”) is a family of compact, low-cost air vehicles designed for a wide range of missions. CMMT’s all-digital design is compliant with Weapon Open System Architecture requirements, enabling rapid upgrades to meet emerging threats while avoiding vendor lock. Its modularity offers mission flexibility; subsystems like seekers, payloads, and engines can be readily replaced to meet new requirements.

Lockheed Martin is flying CMMTs with two configurations: an-air-launched variant that deploys via U.S. Air Force airlifters, fighters and bombers to put affordable mass on target, and a smaller long-range launched effect that deploys from rotary-wing platforms.

With a focus on agility and speed, Rapid Dragon marked a departure from the traditional development template for executing defense industry programs. CMMT represents an even more transformational approach.

A focus on model-based engineering has enabled Lockheed Martin to develop catalogs of mature all-digital missile systems and software architectures to maximize component reuse and commonality across programs. Selecting applicable and proven designs to baseline CMMT has radically accelerated development. For example, we reduced the time required to get to a preliminary design review—a major milestone—by 50 percent.

Applying commonality to a new design accelerates development, boosts maturity and saves time and money—savings we pass on to our customers. This is agile synergy that only a company like Lockheed Martin, with its broad portfolio of proven products and deep bench of engineering talent, can leverage.

Leveraging transformational model-based engineering tools has enabled Lockheed Martin engineers to dramatically accelerate CMMT development, lower cost and boost maturity.

Above all else, CMMT is a manufacturing program; it must be 100 percent producible from the start. Make it low-cost, producible and scalable first, then integrate performance-enhancing and mission-specific capabilities as use cases and threats emerge. This means bringing production and quality engineers onto the program from the start to ensure every system is producible from day one.

CMMT’s open and modular design lays the foundation for distributed supply chains and production lines that can surge to meet customer demands. Agile and modular production cells will enable us to rapidly replicate CMMT production lines across the United States and the world as needed to meet escalating orders. This distributed approach applies to crucial suppliers as well, to eliminate bottlenecks and provide multiple sources for subsystems for rapid surge support.

And when it comes to production, we have a skilled workforce that knows how to manage supply chains and solve problems every day on the line.

The Affordable Mass journey we began with the Air Force is well underway. As Rapid Dragon demonstrated, exercising extreme agility is nothing new to us. And we are moving out with a modular missile and manufacturing-first approach to ensure that U.S. Air Force aviators and other stakeholders have the weapons they need when they need them. So they are as ready to take the fight to the adversary on day 100 as on day one.